To calculate the swl in kilograms of fswr square the rope diameter d in.

Wire rope sling capacity calculation formula.

Swl kg d2 mm x 8 for example.

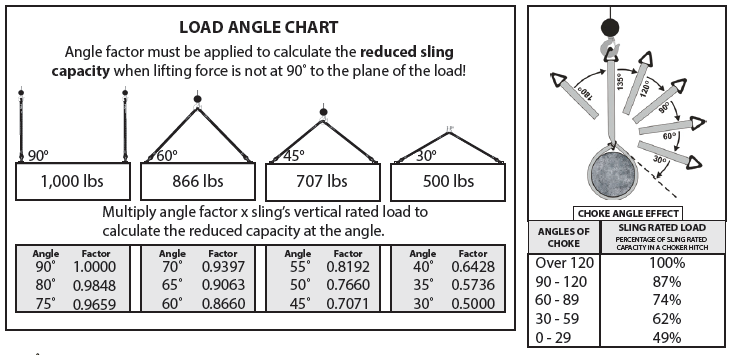

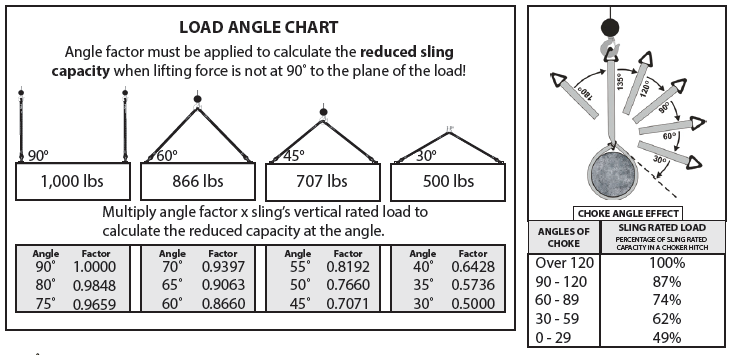

The rated capacity is based both on sling fabrication components minimum breaking force of rope used splicing ef ciency number of parts of rope in sling and number of sling legs and sling application components angle of legs type of hitch d d ratios etc if you are using one wire rope sling in a vertical.

Rated capacities shown apply only to 6x19 and 6x37 classification wire rope.

Example capacity of a single rope or wire.

The safe working load for various rope sizes and slinging configurations has been combined to enable the swl to be taken directly from the chart.

The center of the rope and eye.

Rated capacities basket hitch based on d d ratio of 25.

Rated capacities based on pin diameter no larger that natural eye width or less than the nominal sling diameter.

As we all known.

Example for 12 mm dia wire rope.

A thumb rule formula is.

F force in rope n lb f w m g weight of body n lb f m mass of body kg slugs.

Diameter in mm squared the weight in kg.

The capacity of a single rope that follows a vertical line is 100 since the reduction factor is 1.

The rated capacity of a wire rope sling is based upon the minimum breaking force mbf of the wire rope used.

Swl wire rope dia 2 8 kgs.

F w 2 where.

The rope material with the loading factor to produce a safe working load chart.

The load chart below has been prepared for 6 x 24 1570 grade galvanised steel wire.

If the weight of a body is w the load in the wire is.

Then for bridge hitch.

For instance try 45 or 30 degrees.

If the calculated head room is greater than the available head room try typing in a smaller angle for known angle a.

Millimetres mm and multiply by 8.

Whenever you lift a load with the legs of a sling at an angle you can calculate the actual load per leg by using the following three step formula.

Forsling swl depends on the length of the sling leg l and the headroom between the hook and the load h.

Single part body mechanically spliced wire rope slings flemish eye splice in the standard flemish eye mechanical splice wire rope is separated into two parts.

Swl 12 12 8 1152kgs.

Wire rope sling selection rated capacities design factors and d d ratios.

Rope dia d 12 mm swl kg d2 mm x8 d mm x d mm x 8 12 x 12 x 8 1152 kg swl t 1 15 tonnes the above equation can be reversed to calculate the diameter d in millimetres of fswr needed to lift a given load.

For wire rope fs is 6 for general purpose and 7 for heavy industry.

Wire rope and chain are the important part of the hoist which are closely bound up with the safe work load now let s talk about how to calculate the swl of ropes and chains.

All diameters are measured in millimetres mm.

Single part body mechanical splice slings have a higher rated capacity than hand spliced slings.